Glass-based materials are often sensitive to being exposed to high voltage electron beams. In addition, UniVac is a variable pressure mode which allows the user to observe samples that cannot be sputter coated with metals. Products made of flat glass can be seen in our daily life in the form of windscreens, glass windows, solar panels, furniture parts, electronics, or in the form of containers such as bottles, jars, etc.

Inclusion in glass

- Glass fibres are materials consisting of extremely fine filaments glass that is connected in a compact form. Such fibres have good thermal and acoustical properties and are therefore commonly used in home insulation.

- Advanced glasses such as oxide, silicates, phosphates and borosilicates have good resistance to thermal shock, a variety of special optical properties as well as good chemical resistance. These materials are widely used in industry and their use in optical fibres is one example of their many applications.

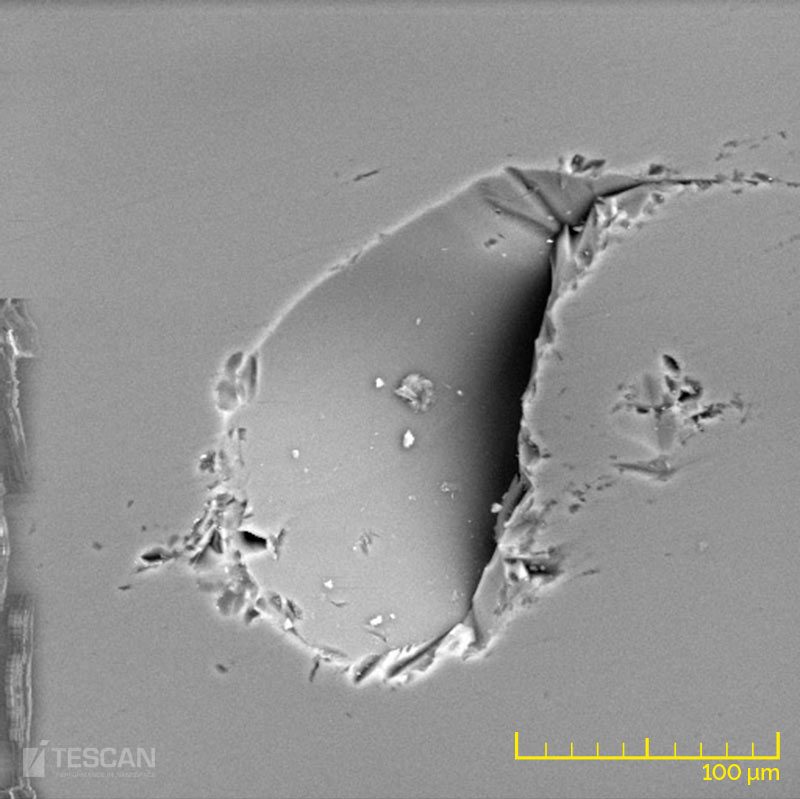

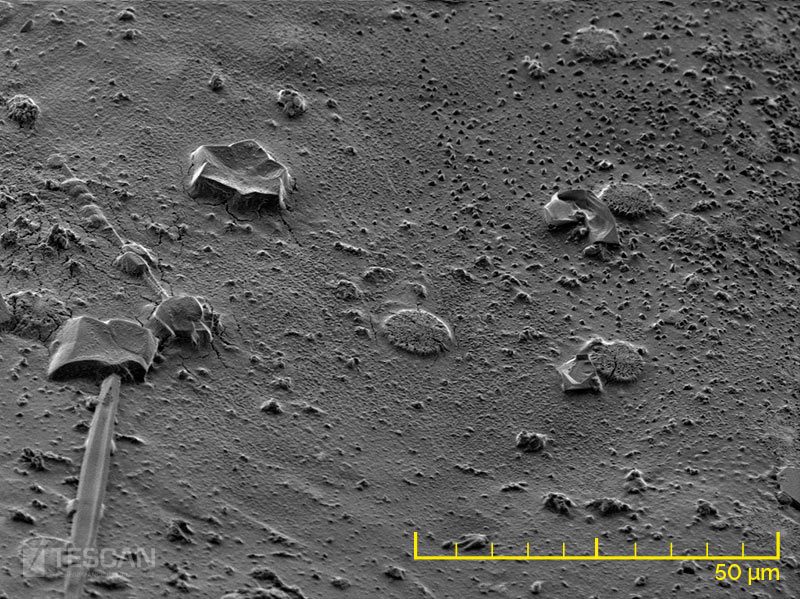

- Defect on the Glass surface

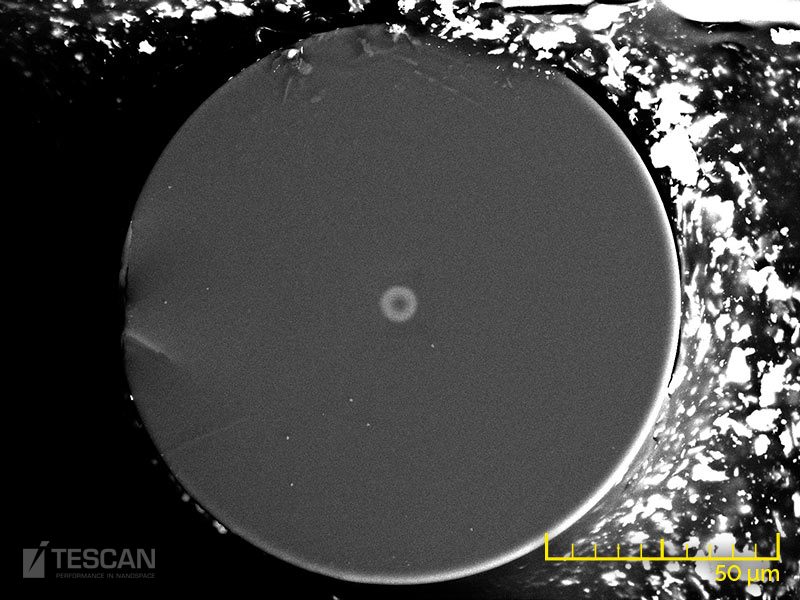

- Glass Optical fiber

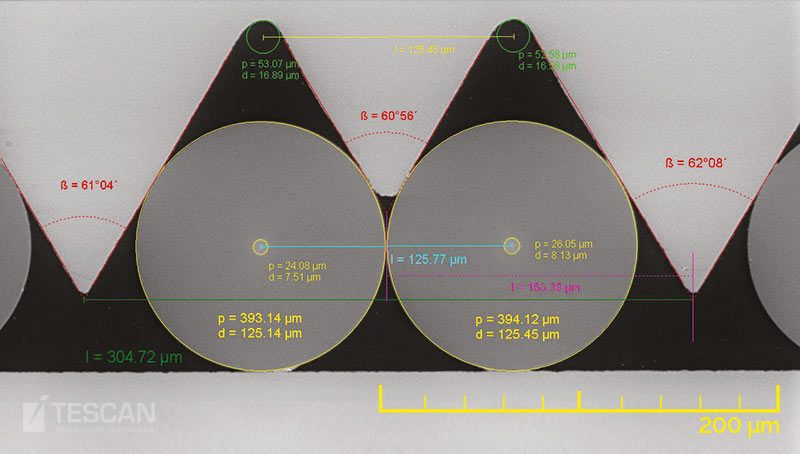

- Glass Optical fiber in matrix with measurement

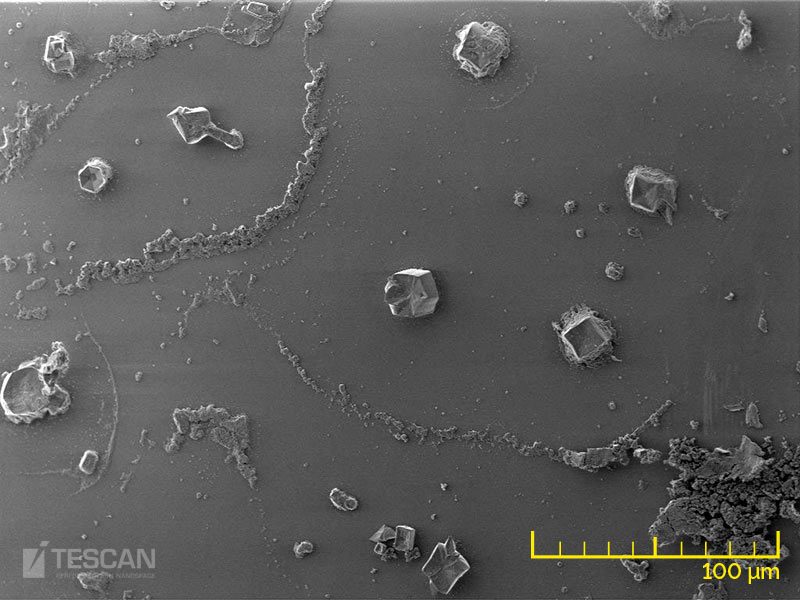

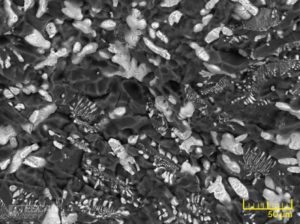

- Glass – growing of the crystals – overview

- Glass – growing of the crystals – detail