For the purposes of studying these materials, TESCAN FEG-SEMs provide the highest resolution imaging even at low accelerating voltages. The variable pressure mode UniVac and the LVSTD detector are especially aimed for samples that cannot be prepared by using standard methods or coated with metals. Additionally Micro-CT allows researchers to non-destructively visualize internal features such as porosity, fibre alignments, and phase distributions. Dynamic CT allows the researcher to visualize 3D changes in internal structures while under loading.

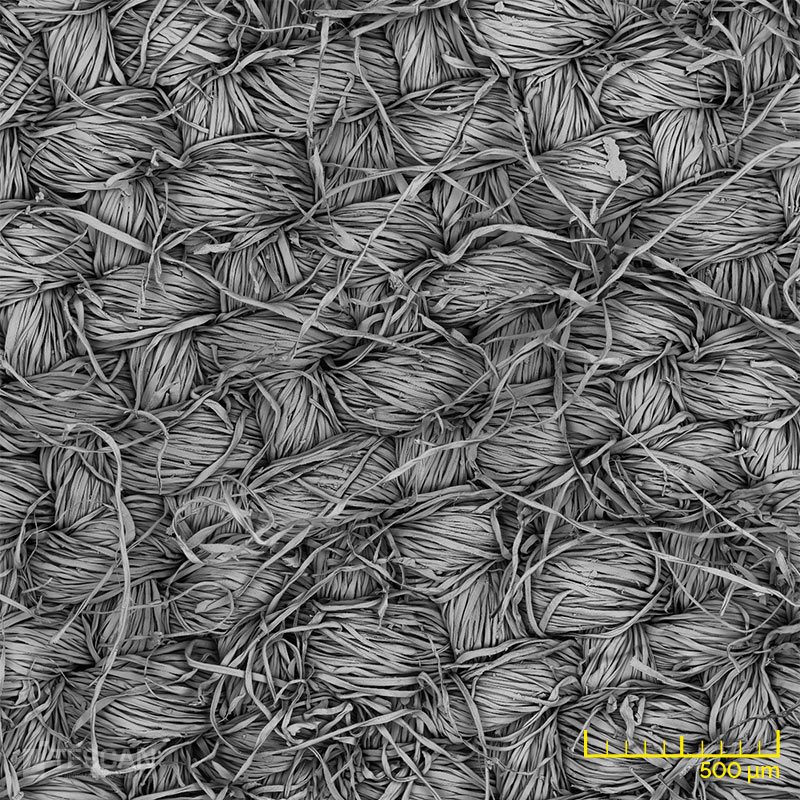

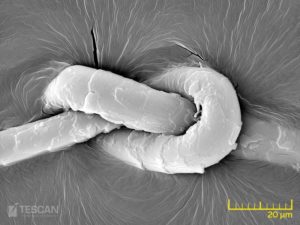

Cashmere fibers

- Textiles can be produced from a wide range of materials. These materials include those of animal origin (such as wool and silk), materials extracted from plants or shrubs (such as cotton, flax or jute), materials of mineral origin (such as glass, fibres and asbestos), and synthetic materials (such as polyester or nylon).

- Textiles can be made with different properties depending on the type and thickness of the particular fibre.

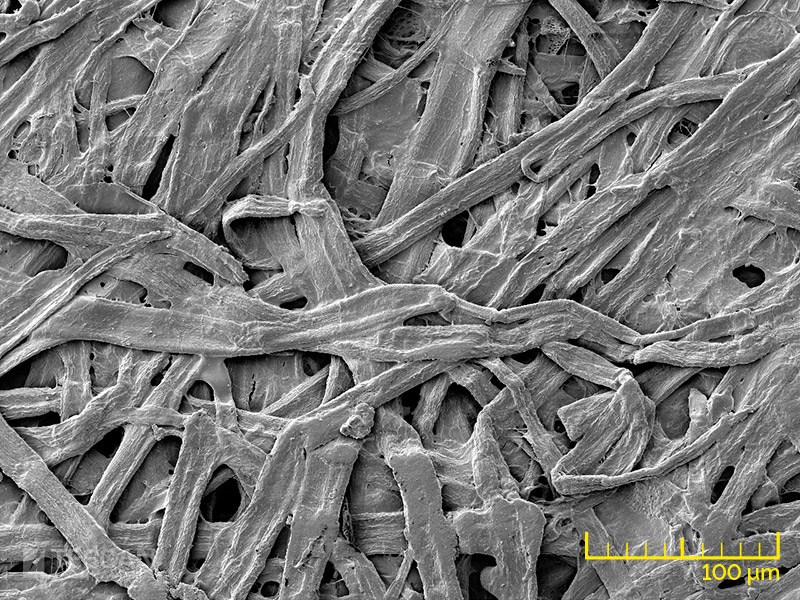

- Paper is a material which is made by pressing fibres such as cellulose pulp. It is used throughout our life in packaging, construction processes, etc.

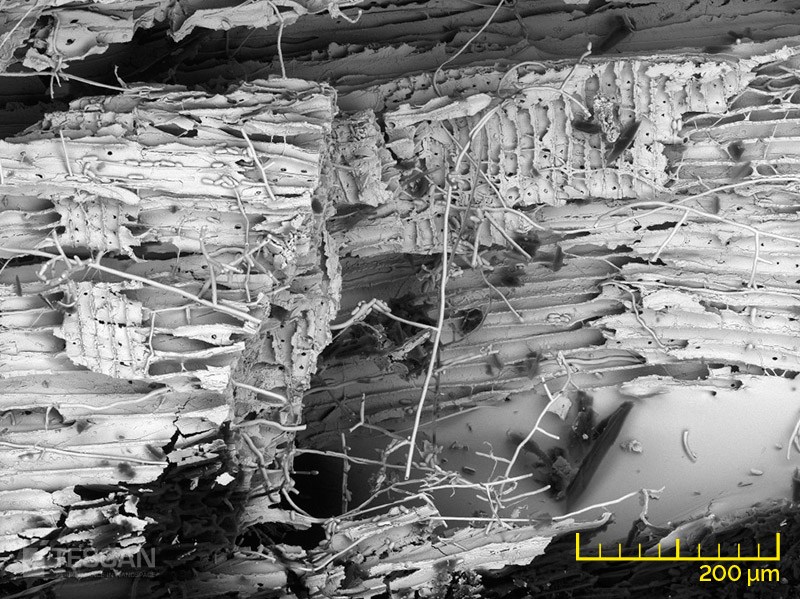

- Wood is an organic material that is used in the construction and furniture industry for building structures. Other wood products include glued laminated timber, wooden structural panels, plywood, oriented strand boards and composite panels.

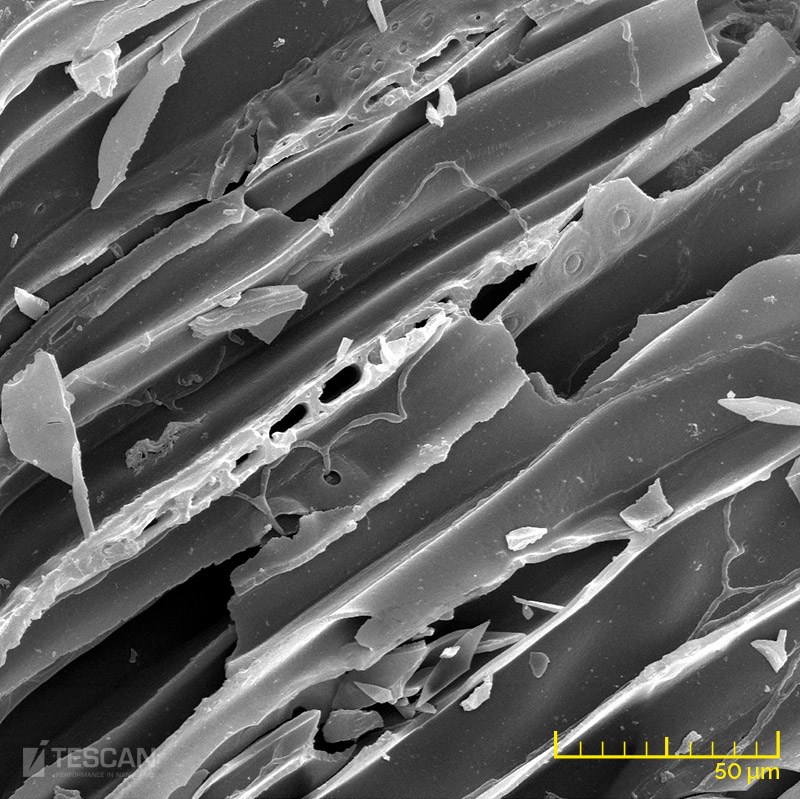

- Structure of cotton

- Structure of wood

- Wood

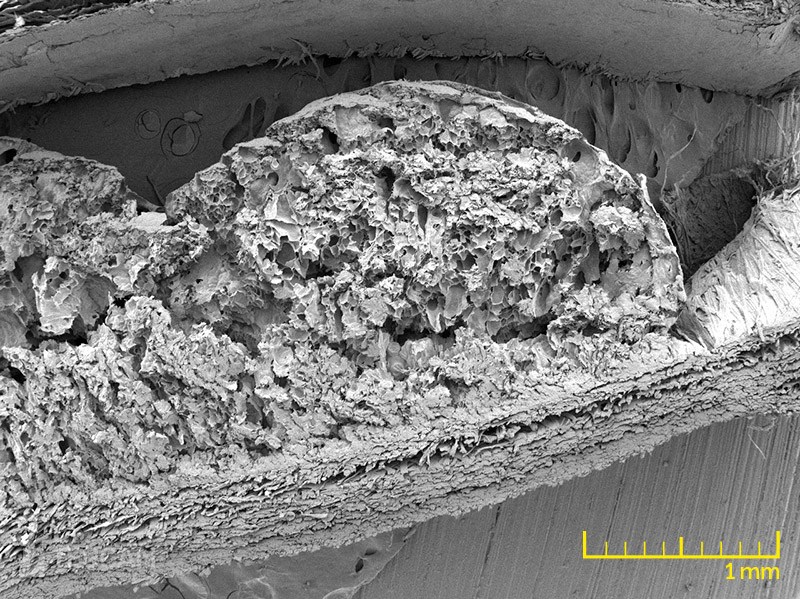

- Paper with the layer of polymers

- Paper packing material