Residual stresses are stresses that are present and locked in materials in the absence of external forces or stressing loads. The origin of residual stresses is often caused at some stage during manufacturing processes. Casting, welding, heating or cooling treatments, molding, milling, bending, rolling, forging among others, are all production processes in which residual stresses can potentially be introduced. Residual stresses can potentially cause materials to rupture, abrupt material failures, deformation, or other problems that negatively impact on their quality, performance and lifetime. It is therefore important to have effective methods and analytical techniques that enable reliable measurements of residual stresses. Scanning Electron Microscopy (SEM) and the Focused Ion Beam micromachining technique combined with Digital Imaging Correlation (FIB-DIC) enable sample analysis that help quantify residual stresses. With FIB-DIC standard geometries are milled using FIB and the surface displacements resulting from relaxation are captured with SEM images using digital image correlation software.

This Good Practice Guide is a key output from the iSTRESS project aimed at providing users with a robust methodology and practical advice for making reliable residual stress measurements on their own systems and materials using the FIB-DIC technique. Within the iSTRESS project a wide range of different FIB-SEM systems including TESCAN FIB-SEM microscopes were used.

Want to learn more about this project and technique, please download the Guide below.

- TESCAN LYRA3 FIB-SEM

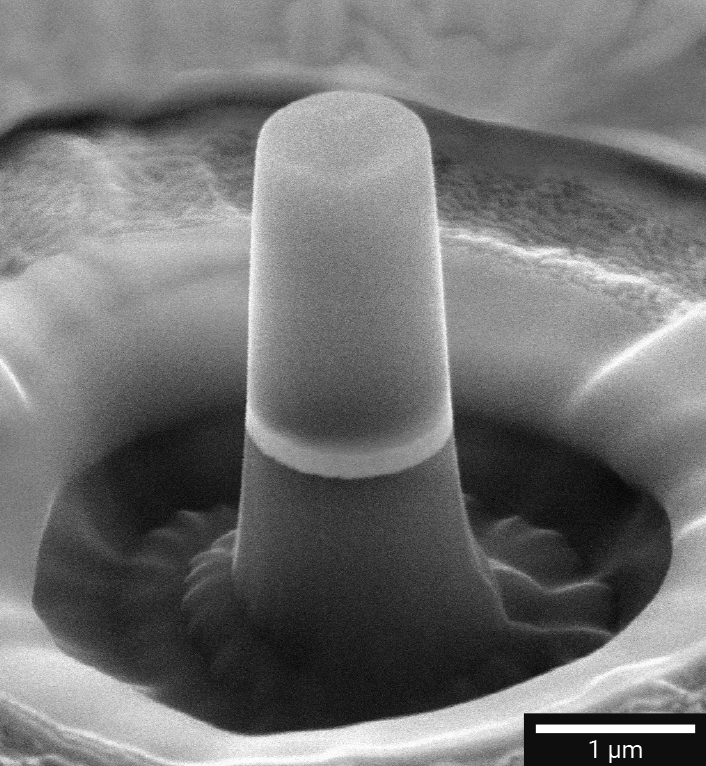

- Micropillar for mechanical testing. Image taken from the TESCAN Materials Science brochure.