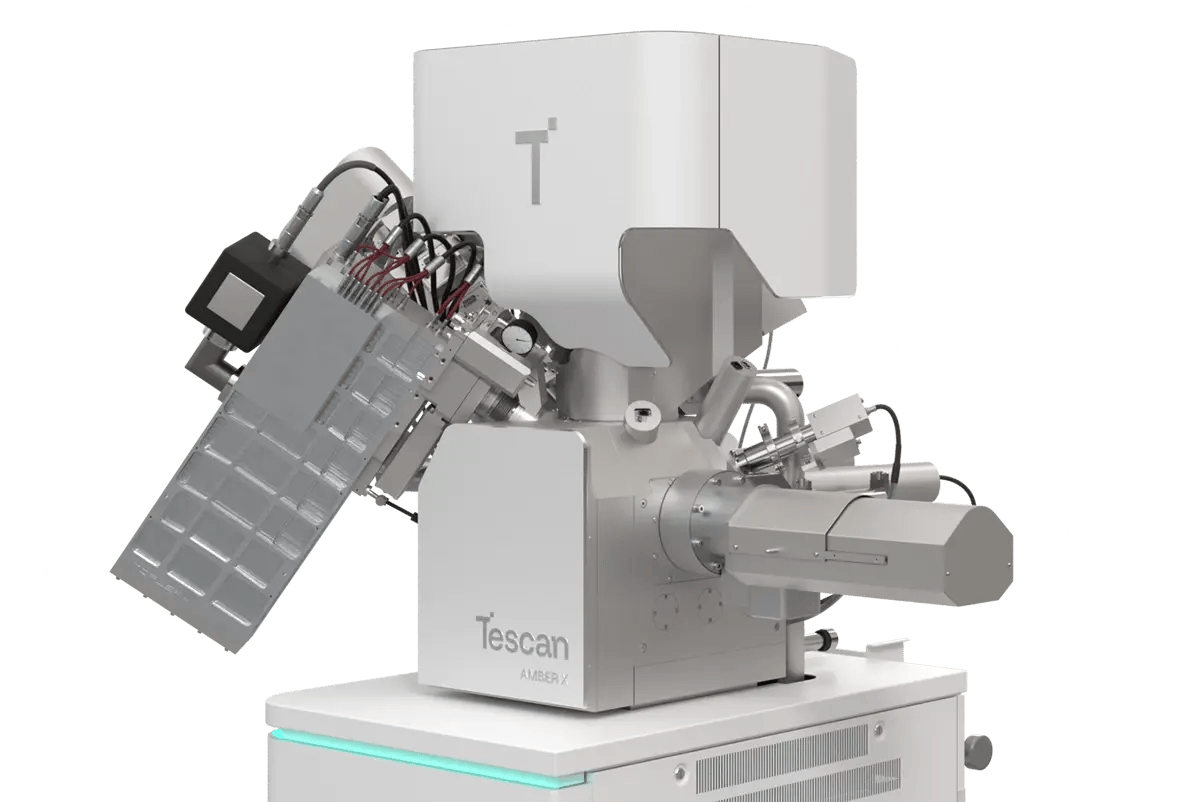

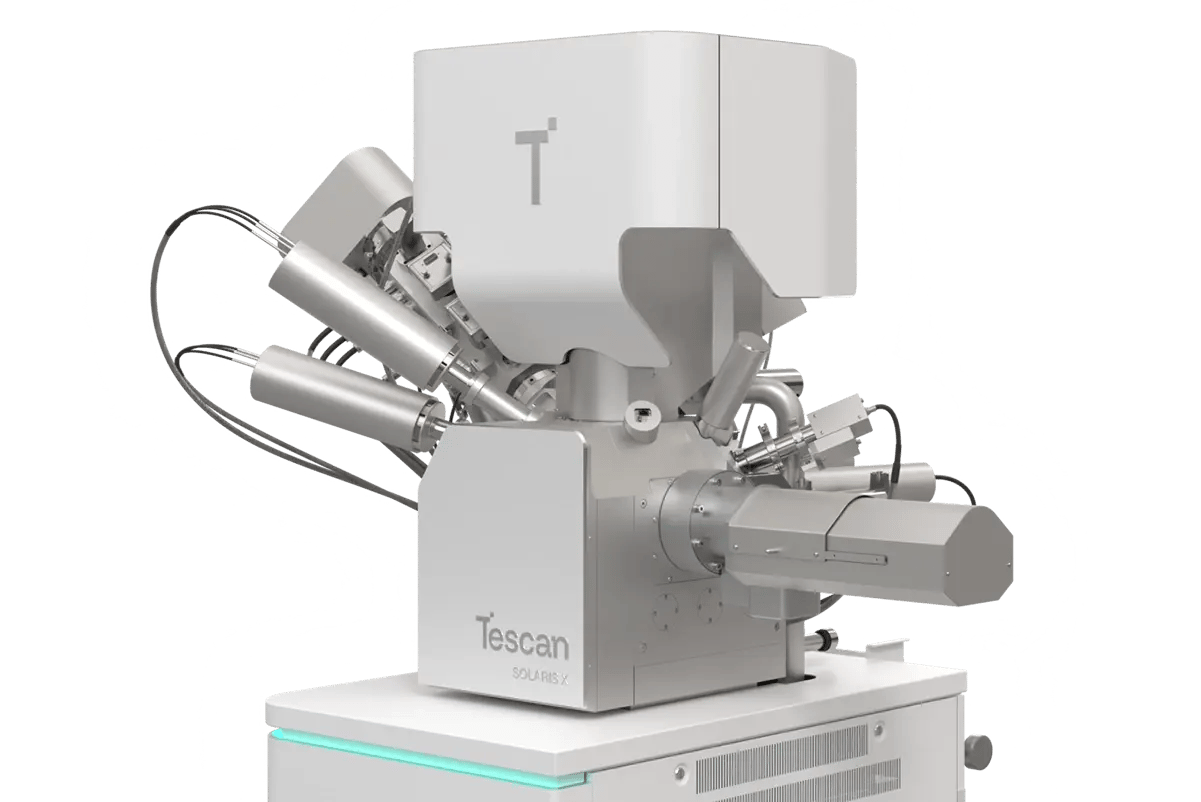

Achieve precise fault isolation in semiconductor failure analysis without damaging fragile device layers. Tescan FIB-SEM workflows deliver smooth delayering with plasma milling and CAD-assisted navigation.

Endpoint detection ensures you reach the circuit of interest without artifacts, while in-situ imaging and probing streamline fault localization.

Enable reliable results that strengthen device performance and accelerate decision-making in semiconductor development.

_1x.webp?width=214&height=206&name=MicrosoftTeams-image%20(64)_1x.webp)