For this purpose, a series of analyses and the characterisation of product reaction effect on electrodes that take place especially at their surface and interface regions is essential. This requires analytical techniques capable of differentiating chemical states with high sensitivity and high spatial resolution.

This has led to extensive investigations on Li-ion batteries as these are envisaged as the basis for high power density secondary sources for electric vehicles and storage devices for the smart grid. Vital performance of Li-ion batteries such as cycle life, internal resistance and capacity, are closely related to the microstructure of electrodes. Solid electrolyte interphase (SEI) has proven to be crucial in increasing the performance and life of lithium-ion batteries. It is, therefore, necessary to fully understand the mechanisms and reactions which lead to the formation of SEI layers on the electrodes in Li-ion batteries.

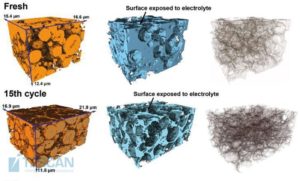

3D FIB-SEM reconstructions of electrodes at different cycling stages: in terms of active particles (left), porosity with carbon black and all other non-active materials (middle), and the interface between the phases (right). Courtesy of Dr Bohang Song, the University of Oxford.

- To this end, TESCAN offers a unique FIB-SEM time-of-flight secondary ion mass spectrometer (TOF-SIMS) integration which allows technologists and scientists working in the battery industry to perform high-resolution surface analyses such as depth profiling and elemental distribution maps to shed light on SEI in Li-ion batteries.

- The 3D Tomography Advanced software combines the 3D imaging with micro-analytical signals which make 3D EDX and 3D EBSD analyses possible.

- High-resolution imaging reveals microstructural information at the level of the composite framework consisting of the spherical microparticles of the active material held together by the polymer matrix.

- Micro-CT allows the non-destructive, 3D, investigation into the interior structures of a variety of battery types. Dynamic micro-CT provides researchers with a lab-based method to observe changes in battery micro-structure while undergoing operations such as cycling or heating.

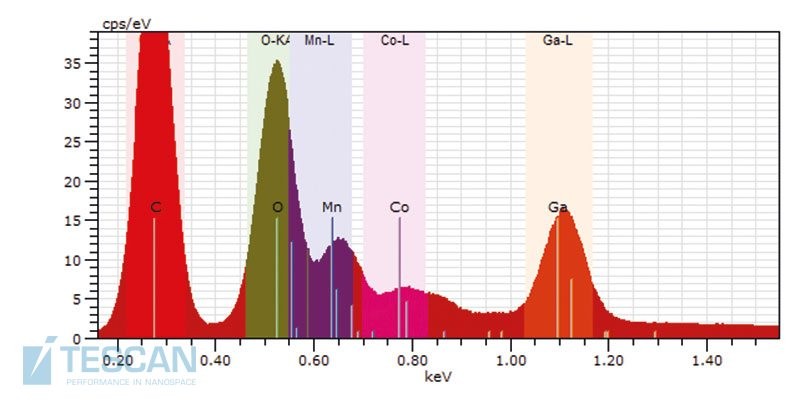

- EDX spectrum of a Li-ion battery electrode.

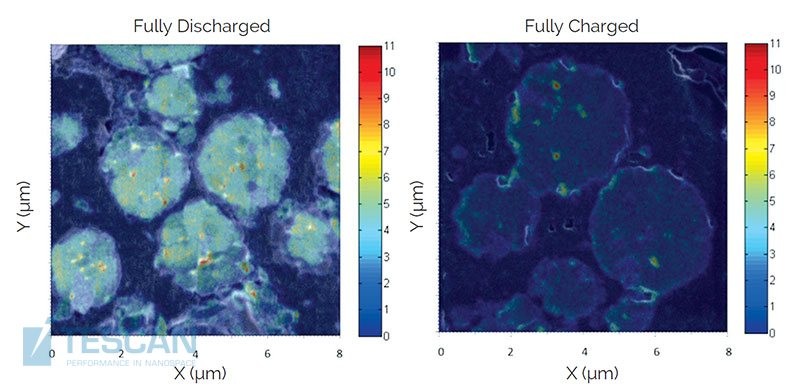

- Correlative imaging showing TOF-SIMS Li distribution maps overlaid on FIB-secondary electron images for fully discharged (left) and fully charged (right) cathode material. The full field of view is 8 μm.

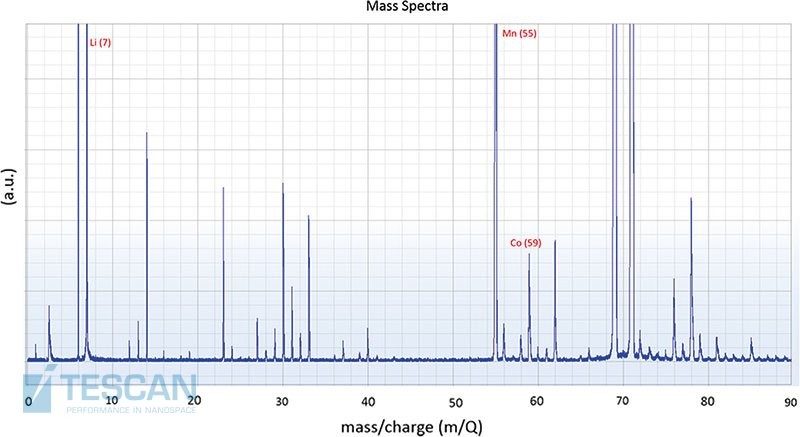

- TOF-SIMS spectrum of Li-ion battery electrodes after 15 charging cycles. The Li-ion peak of the main isotope (7 m/Q) is clearly visible.

- Multiscale imaging of 18650 Li-ion battery