Rocking stage technology is the most efficient method for achieving the artifact-free FIB cross-sections and for cross-section polishing to improve final sample quality for semiconductor failure analysis or advanced materials characterization. By tilting the plane of the cross-section, a rocking stage adjusts the sample’s position to compensate for the variation in material removal rates that occurs with FIB milling.

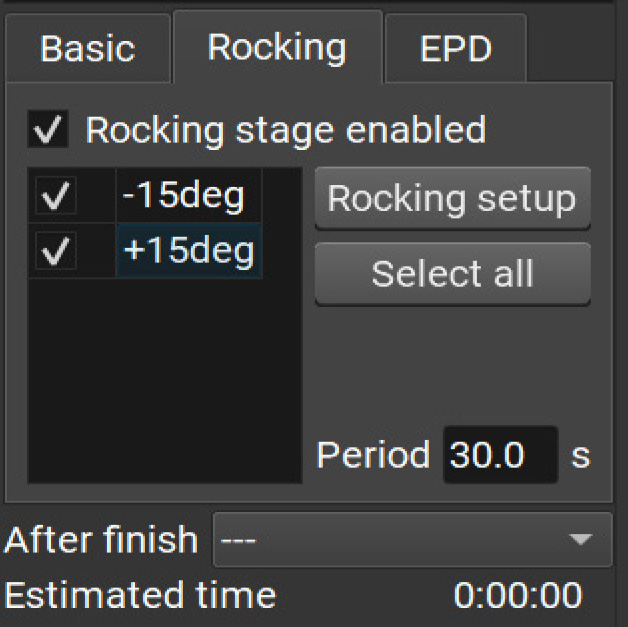

The TESCAN Rocking Stage is fully compatible with TESCAN hardware and software to create an integrated solution for more efficient workflow execution and improved milling speed and accuracy. Among the capabilities of the TESCAN Rocking Stage is Y-axis tilt perpendicular to main stage X-axis tilt, and real-time SEM monitoring of the milling process for precise end-pointing at your region of interest. The Rocking Stage setup wizard allows users to set-up automated milling and rocking workflow, including defining and storing two or more rocking positions. And the TESCAN Rocking Stage design preserves the versatility of the FIB-SEM system, including full compatibility with the load lock, Beam Deceleration Mode (BDM) and the RSTEM detector.

TESCAN Rocking Stage

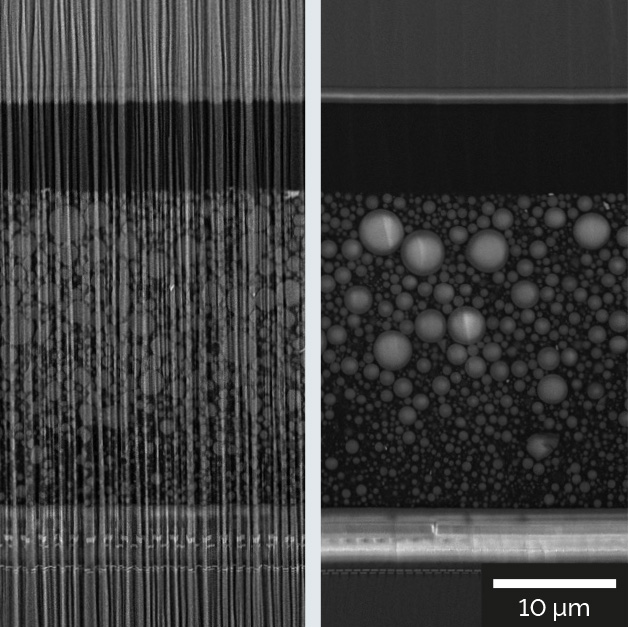

- Mitigate FIB-induced curtaining artifacts caused by the preferential milling rates for hard and soft material mixes, surface topography or internal sample geometry ( vertical interconnects in semiconductor devices)

- Mitigate curtaining artifacts during the FIB-SEM tomography acquisition process

- Achieve precise end-pointing at your region of interest by using the SEM for live monitoring of the milling and tilting process

- Maximize sample preparation throughput with the TESCAN Rocking Stage set-up wizard to automate the rocking procedures and positions

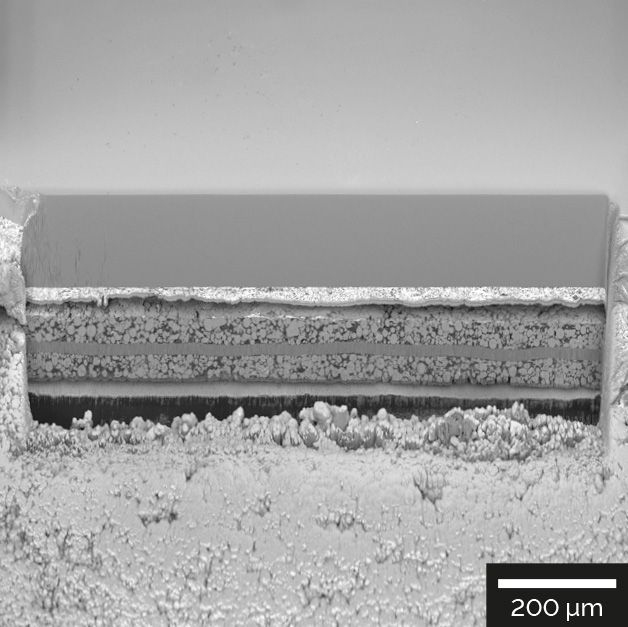

- 1 mm wide cross section of a Li-ion battery electrode

- Cross section polished without (left) and with (right) the TESCAN Rocking stage

- Software to control the TESCAN Rocking Stage is fully integrated into the Essence™ GUI