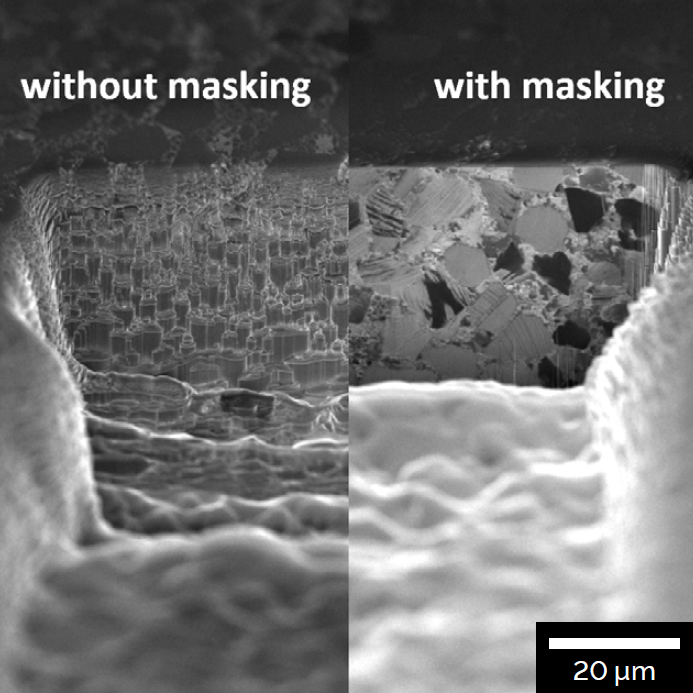

High-current plasma FIB systems are now indispensable in both the semiconductor industry and in materials research for improving material removal rates and the final surface quality of cross sections or 3D tomography samples. Unfortunately, plasma FIB milling can also produce ripple artifacts, which occur as terrace structures in the resulting cross section. The presence of such artifacts can make it more difficult to identify a defect or other features. TESCAN’s TRUE X-Sectioning utilizes a masking principle that was first implemented on broad ion beam milling systems, to provide a time-saving method for managing beam tails and suppressing terrace artifacts — without sacrificing the high beam current advantage of plasma FIB.

Key Benefits

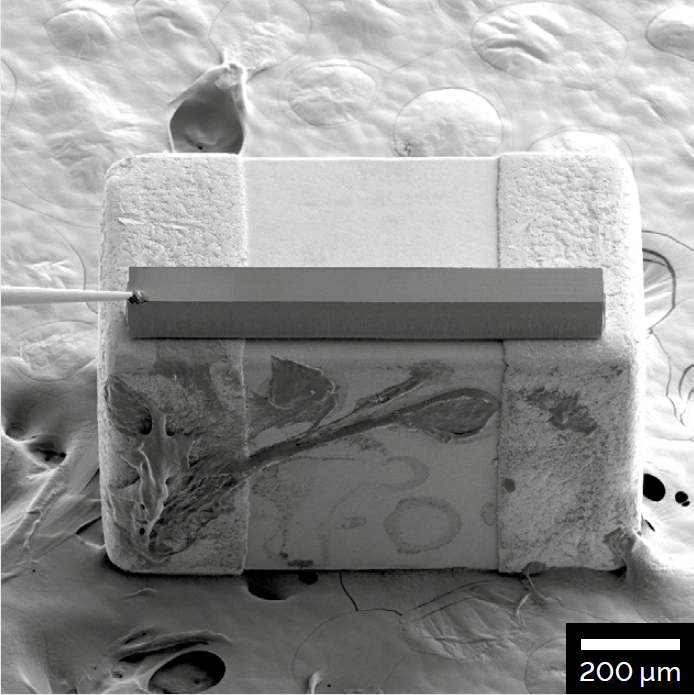

- Supress ion beam-induced ripple artifacts on hard materials, composite samples, or biological resin-embedded samples with our easily implemented precut silicon masks

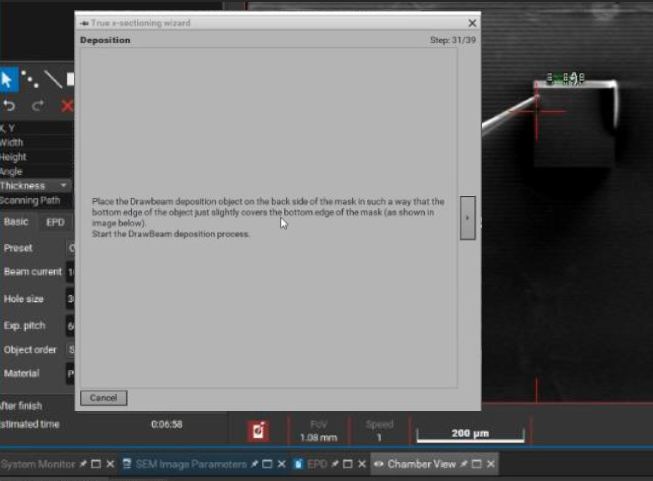

- Streamline the mask placement workflow using the Mask Placement wizard feature of TESCAN’s Essence™ GUI, which guides users through the complete placement, milling and lift-out process

- Achieve the ultimate cross section quality while maintaining the advantage of high current plasma FIB milling by combining TRUE X-Sectioning, to achieve the optimal milling beam, with TESCAN Rocking Stage, to remove any visible curtaining

- Select from a variety of application-specific masks included in the TRUE X-Sectioning package to achieve the best possible surface quality at the target area

Applications

- High-throughput plasma FIB cross-sectioning of challenging materials such as SiC, SiN, ceramics, diamond, glass, tungsten carbide, geological materials and biological resin-embedded samples

- Cross-sectioning of composite materials, highly topographical samples and samples formed from alternating hard and soft layers or porous layers

- Protect surface features and assure optimal surface quality during plasma FIB cross-sectioning for 3D tomographic analyses