Different ore textures, as well as different mineralogy of the ore, can cause significant changes in the plant performance. Automated Mineralogy (AM) is a very important diagnostic tool in extractive metallurgy as it adds ore and particle mineralogical properties to traditional bulk mass, chemical and XRD data. AM is used in project development, for future ore studies and for diagnosing day-to-day plant operations. These are industrial-scale problems and the emphasis is on high productivity and fast retrieval and interpretation of results rather than on classical microscope mineralogical research.

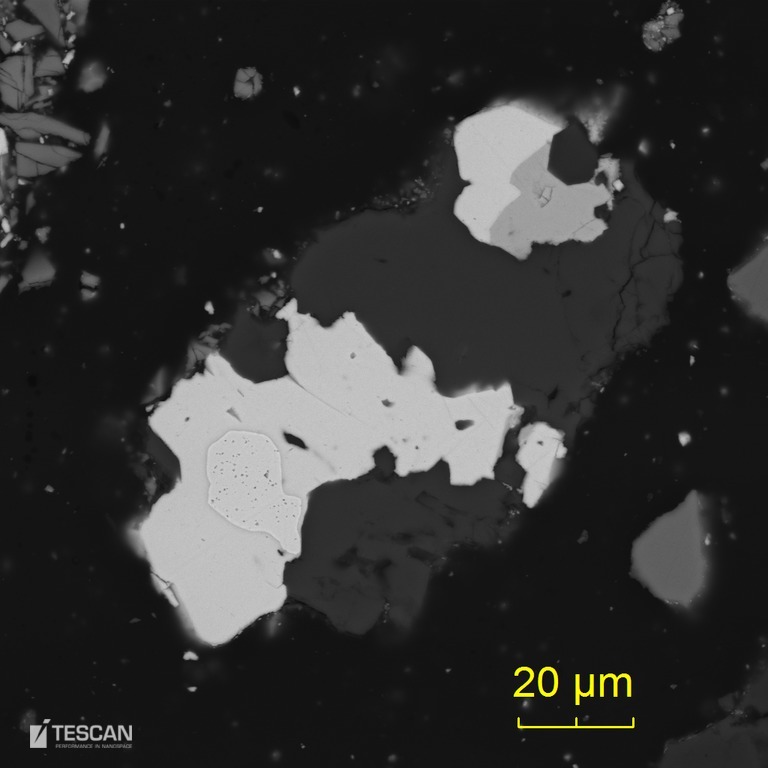

Tantalite grain complexly is intergrown by muscovite

- Large numbers of samples and sampling statistics are required. This means that manual measurements would simply not be fast enough and representative enough. This industry-related work requires automation – Automated Mineralogy analysis. TESCAN brings its own solution. TIMA (TESCAN Integrated Mineralogical Analyzer) is a purpose-built system for automatic industrial use. An additional feature of the TIMA is the TESCAN AutoLoader that takes automation to an even higher level by using a robotic system to load the samples into the SEM chamber.

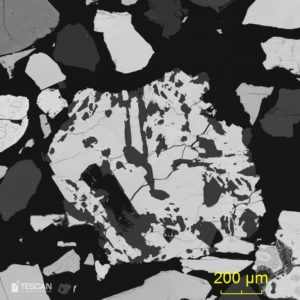

- TIMA automatically evaluates relationships of the individual minerals using backscattered electron (BSE) imaging combined with X-ray mapping from the electron beam sample interaction. The BSE intensity is proportional to the average atomic number of the observed phase. Boundaries among different phases can thus be easily visualized.

- The samples come directly from plant and laboratory tests and are particles ranging in size from a few micrometres to few millimetres. The powder is cast in an epoxy block which is sectioned, ground and polished to a flat smooth finish. The polished samples are coated with a thin conductive layer of carbon. The surface finish is needed to enable calibrated comparisons of the BSE intensities and the collection of representative X-rays.

- The mineral particles are discriminated from the mounting epoxy based on the BSE contrast. The epoxy is considered as a low brightness background and excluded from the analysis.

- To minimise measurement time, the characteristic x-ray spectra for the phase identification are collected only from areas above specified threshold of the BSE intensity. The BSE thresholding can also be used to exclude common rock-forming minerals or gangue and focus the analysis solely on particles containing high BSE intensity phases – typically gold particles or platinum group minerals.

- Mineral identification is based on both the BSE level and the chemical composition of the phase. The minerals are identified automatically based on a set of predefined rules in a mineral classification scheme.

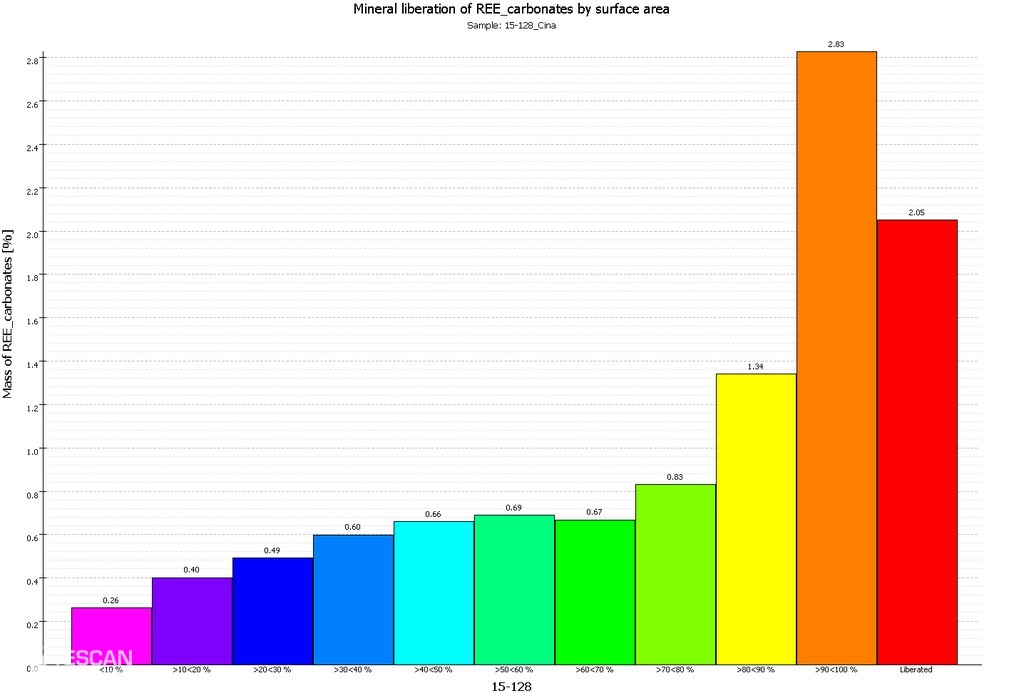

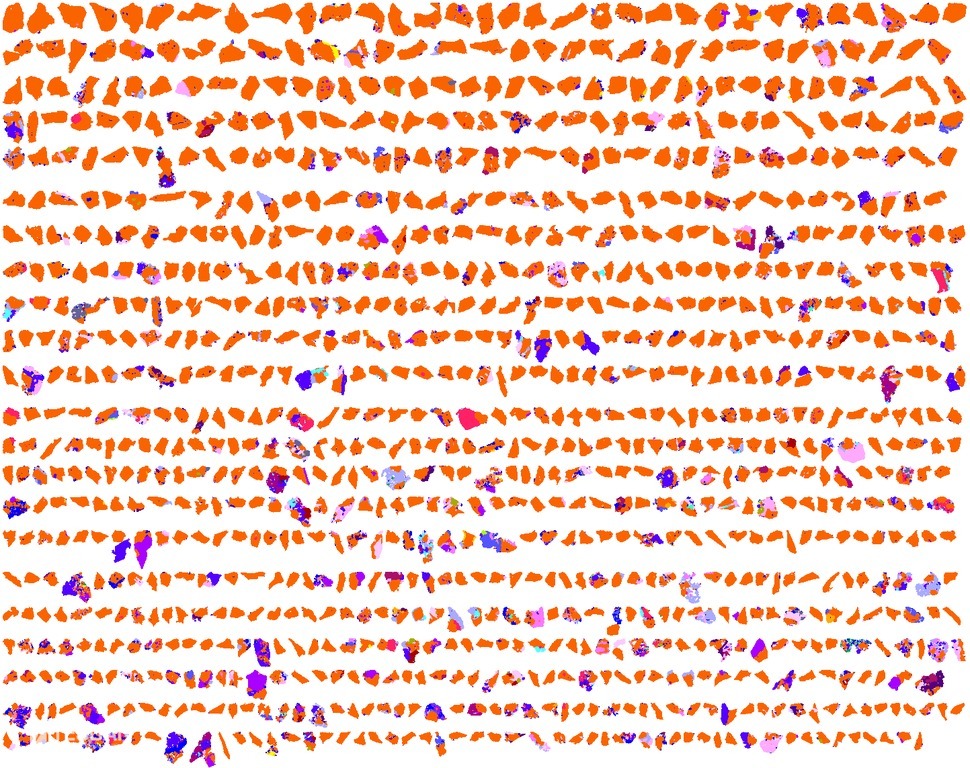

- TIMA generates a modal mineralogical composition of the sample. Each of the mineral grains (segments) is treated as a separate entity whose properties (size, neighbouring grains, extent of the free surface etc.) can be recalled and used to synthesize different outputs valid for the entire sample – association, liberation degree, grain size etc.

- The measured modal volumetric composition of the sample can be converted to the weight of individual minerals using density values from the mineralogical database.

- Based on the mineralogical database, the system can then calculate the average density and chemical composition of the entire sample and compare it to the results obtained by independent chemical analysis.

- Automated mineralogy systems are most commonly used to track causes of low recoveries of metals in the concentrator and dilution of the concentrate. TIMA can provide many relevant answers about poorly liberated grains of the mineral of interest, the presence of gangue minerals influencing the process, the deportment of the valuable metal between minerals, and the occurrence of penalty elements. These are a few examples from many other possible diagnostic results, which can be reported in images, tables, and charts.

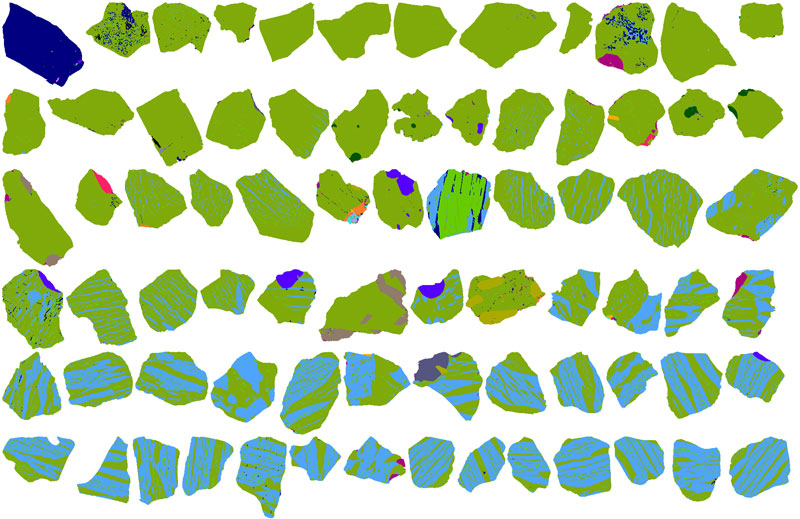

- Heavy mineral concentrate particles sorted according to its Ti content

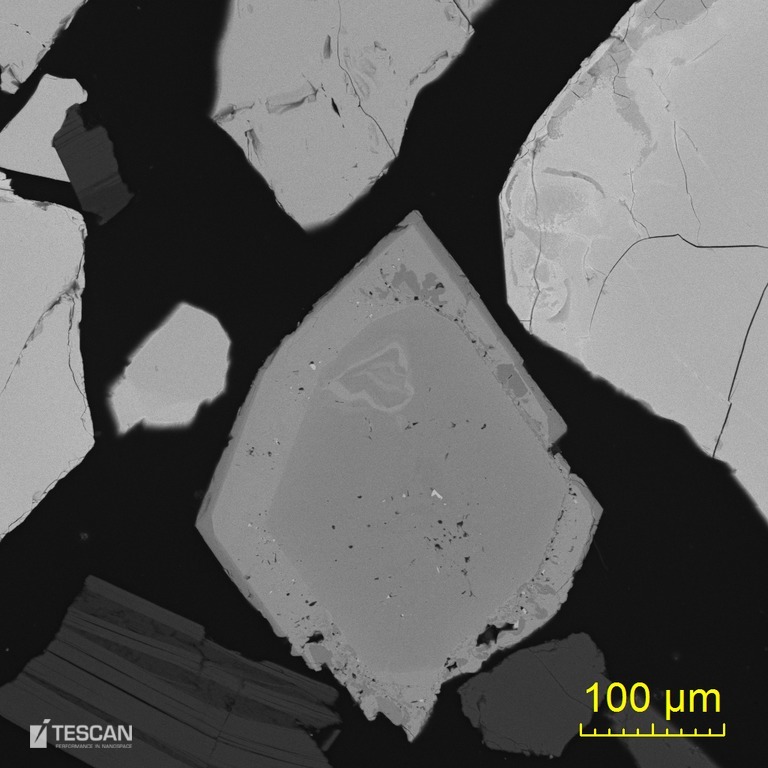

- Zoned hafnon grain as an example of rarely ocuring phases found by means of automated mineralogy

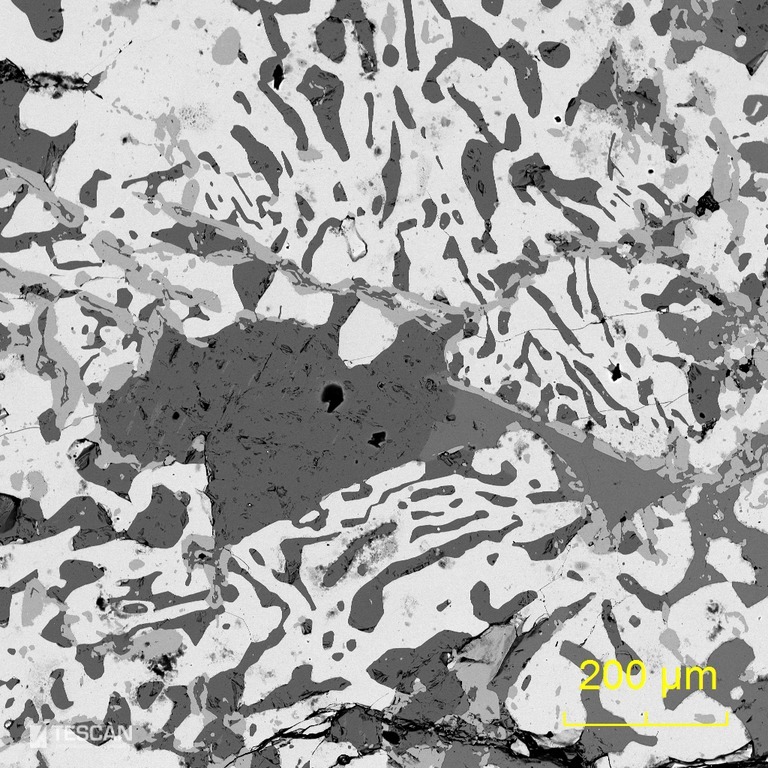

- Complex sulphidic ore from magmatic deposit

- Gold locked in galena

- REE carbonates group liberation degree

- Copper ore particles sorted according to the chalcopyrite content