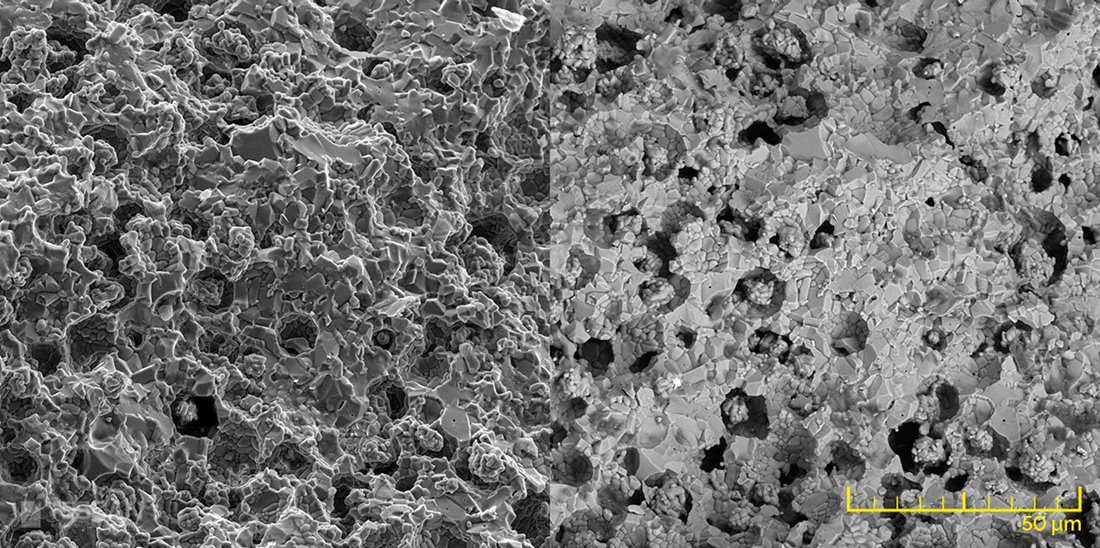

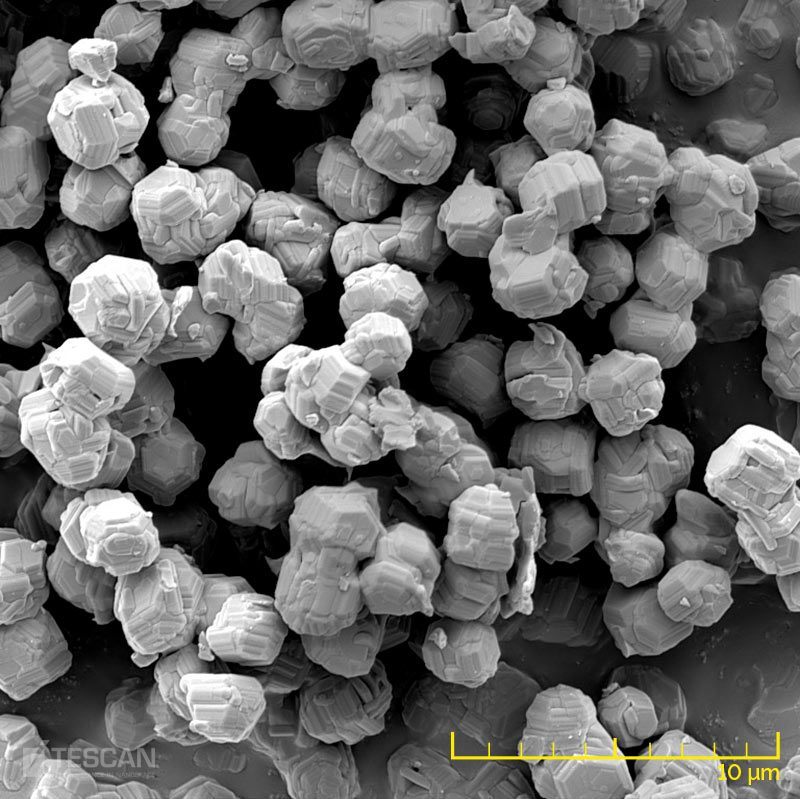

Technical ceramics can be divided into the following groups: oxide ceramics (which contain materials consisting primary of metal oxides such as alumina, zirconia, beryllium and ceria); non-oxide ceramics (materials based on carbides, nitrides, borides and silicates); and composite ceramics (comprising particle- and fibre-reinforced ceramics as well as combinations of oxides and non-oxide ceramics).

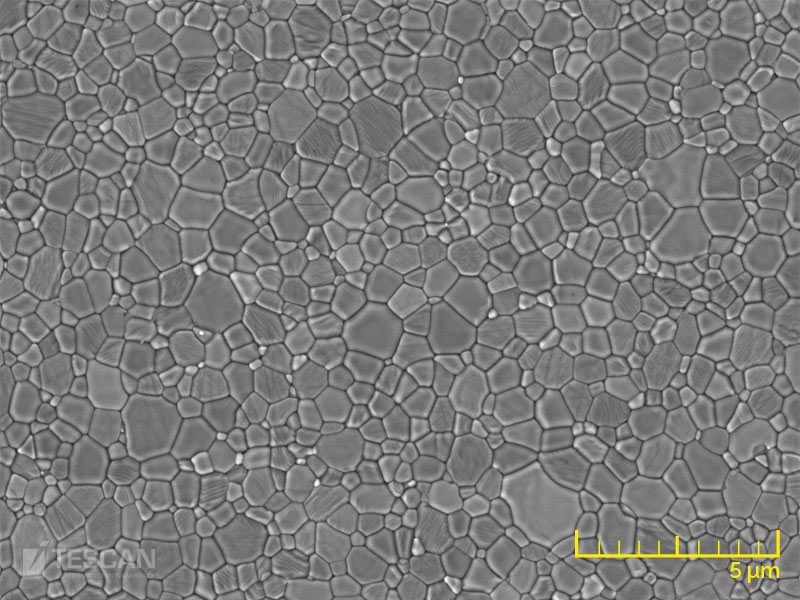

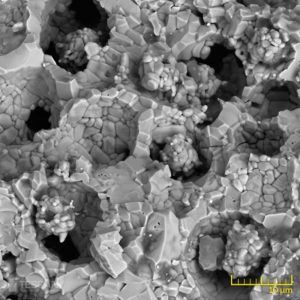

Al2O3– detail (BSE detector)

- Advanced ceramics refers to technical, engineering or industrial ceramics.

- Ceramic materials are very resistant to abrasion and have very interesting mechanical, electrical, thermal properties.

- Advanced ceramics have a wide range of applications in automotive, medicine, electrical and electronic industry.

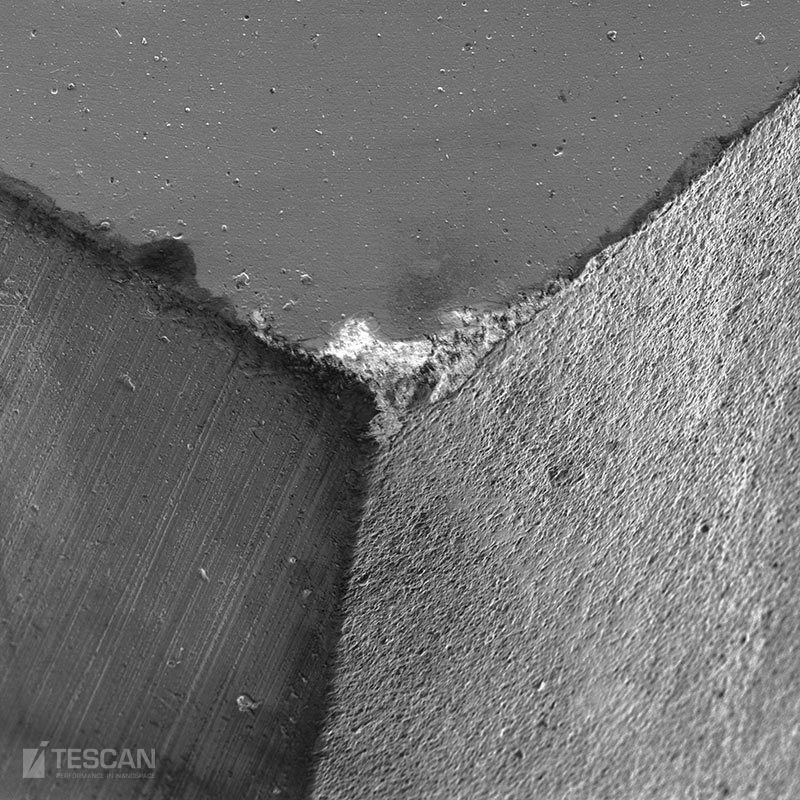

- TESCAN Field Emission Gun SEMs (FEG-SEMs) are ideal instruments for studying advanced ceramic structures at high resolution.

- SEM can be used in combination with the Beam Deceleration Technology (BDT) in order to achieve high-resolution imaging at ultra-low landing electron energies, allowing researchers to obtain superb images of the microstructure of such samples.

- Micro-CT allows researchers to non-destructively visualize internal features such as porosity, cracks, and phase distributions.

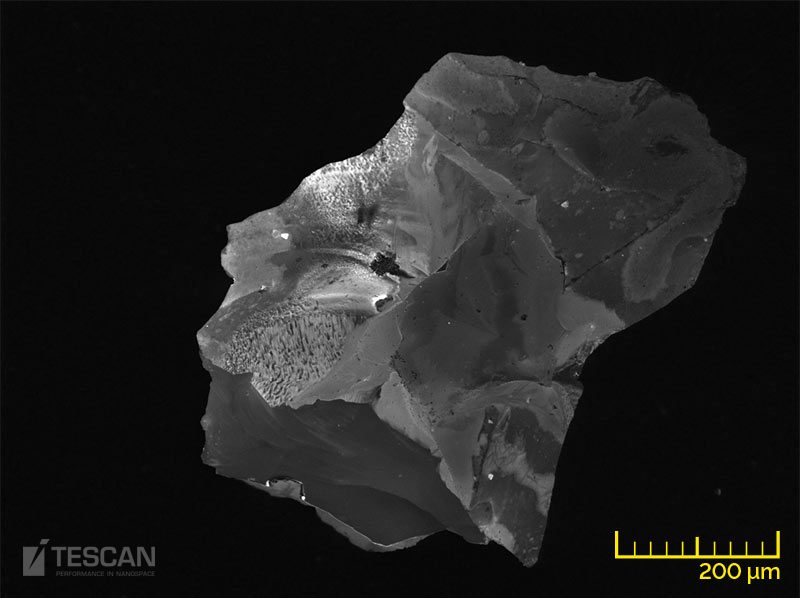

- Al2O3 – overview (SE, BSE detector)

- SiC

- Cutting tool – edge coatings

- Zirconia

- Corund inclusion – Al2O3 + silicates