Electron beam lithography (EBL) uses a focused beam of electrons to draw patterns on a surface covered with an electron-sensitive film (resist). This technique is common for prototyping micro-and nanostructures with specific shapes, dimensions and material composition on various substrates for developing sensors, photonics, plasmonics, spintronics, MEMS, microfluidics, and surfaces for cell growth.

Adding the TESCAN Essence™ EBL Kit to TESCAN G4 series SEM and FIB-SEM instruments creates a multipurpose nanoprototyping tool with both electron and ion beam-based lithography techniques available to users. The Essence™ EBL Kit is an ideal solution for labs that need access to this application, but don’t require a dedicated advanced lithography system. Working in conjunction with TESCAN’s fast electrostatic beam blanker, the advanced EBL software module included in the TESCAN Essence™ EBL Kit controls the entire lithography process from within the already familiar Essence™ GUI.

Adding electron beam lithography to a SEM or even a FIB-SEM creates a powerful solution for micro-and nano-prototyping applications because researchers are able to capitalize on the analytical capabilities of SEM and FIB-SEM following the lithography process to validate structures, dimensions or material composition.

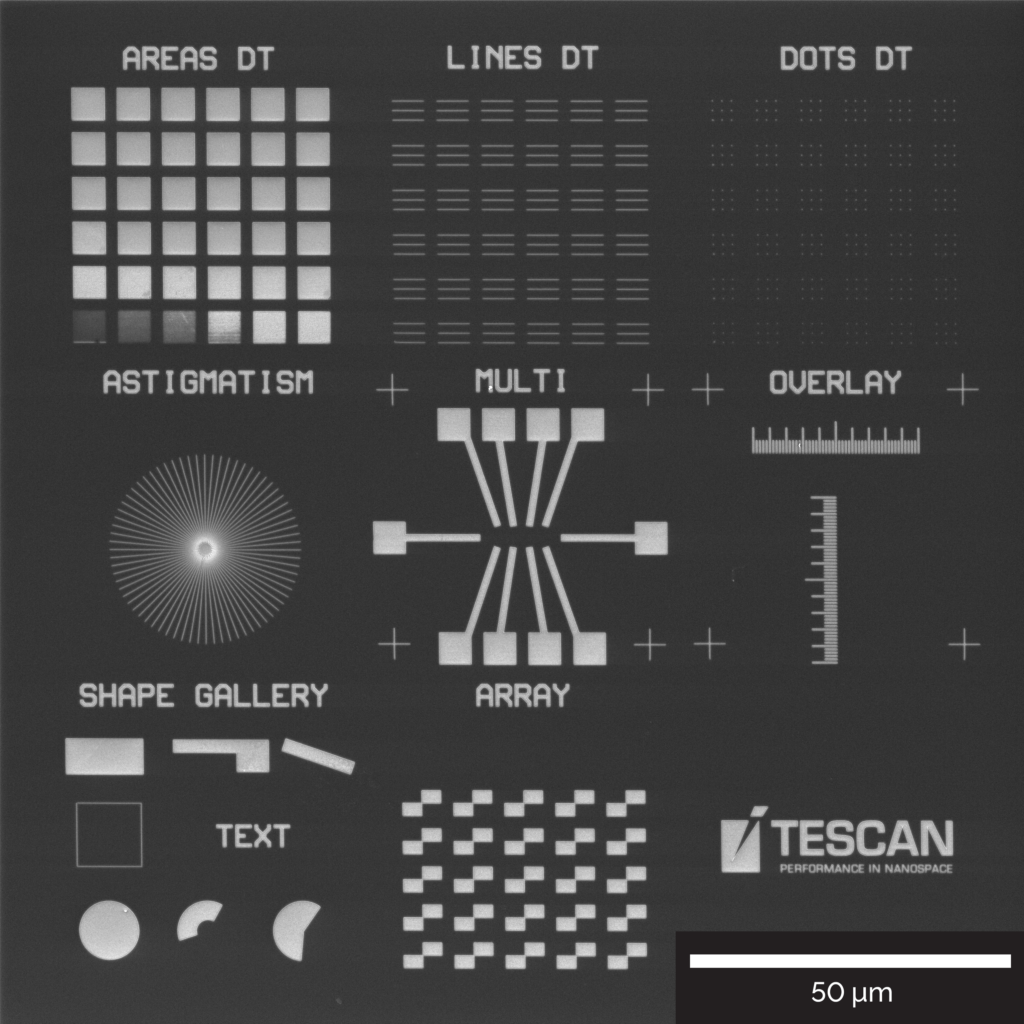

Testing pattern transferred to e-beam resist on the sample using EBL

- Add advanced EBL software and TESCAN’s fast electrostatic beam blanker on a standard TESCAN SEM system to create a complete, cost-effective solution for performing intermediate-level electron beam lithography

- Create a powerful, multi-purpose nanoprototyping tool by adding EBL capability to a TESCAN FIB-SEM system to combine EBL with separately controlled ion beam-based lithography techniques for both basic and applied research

- Control the EBL process through the fully integrated Essence™ EBL software module which features a user interface that is consistent with the TESCAN Essence™ GUI, making it familiar and easy to learn

- Work confidently with the full support of the GDSII hierarchical data format that is used most commonly by EBL community

- Utilize EBL software capabilities to optimize exposure conditions and minimize errors or defects

- Reduce EBL exposure duration by using high-speed electron beam control during the exposure

- Plan your time requirement for instrument use with the exposure time estimate functionality