TESCAN Delayering is a new software module for automated gas-assisted top-down delayering to TESCAN SOLARIS X and AMBER X Plasma FIB instruments. Proprietary gas chemistries combined with the inert ions and speed inherent in Xe plasma FIB provide a powerful solution for rapidly creating artifact-free, site-specific trenches — with maximum planarity and homogeneity and without altering a device’s electrical properties — for rapid access to deeply buried features or defects.

TESCAN Delayering is a new software module for automated gas-assisted top-down delayering to TESCAN SOLARIS X and AMBER X Plasma FIB instruments. Proprietary gas chemistries combined with the inert ions and speed inherent in Xe plasma FIB provide a powerful solution for rapidly creating artifact-free, site-specific trenches — with maximum planarity and homogeneity and without altering a device’s electrical properties — for rapid access to deeply buried features or defects.

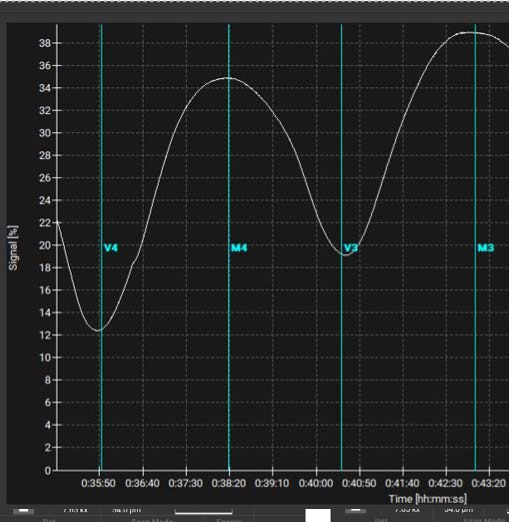

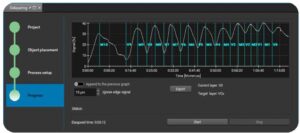

Operating from within the TESCAN Essence™ GUI, TESCAN Delayering uses a step-by-step guided wizard to set-up the required delayering process. Factory-defined templates assure consistent application of all delayering parameters, as well as providing the starting point for users to develop their own recipes customized to their specific devices. Using the selected parameters, the TESCAN Delayering module executes the process automatically for unattended operation, while the plasma FIB provides rapid material removal without Ga implantation or beam damage. At any time during the delayering process, users may monitor the progress by using signal peak recognition in the end-point-detection curve. The delayering process automatically terminates before reaching the target layer.

Following delayering, the device is ready for SEM-based in-situ nanoprobing or electrical characterization. If further investigation is required for root cause analysis, users can then perform high throughput cross-sectioning, TEM sample preparation or compositional analysis to gain further insights into the failure or defect.

Learn more about how TESCAN Delayering will improve physical failure analysis in your lab.

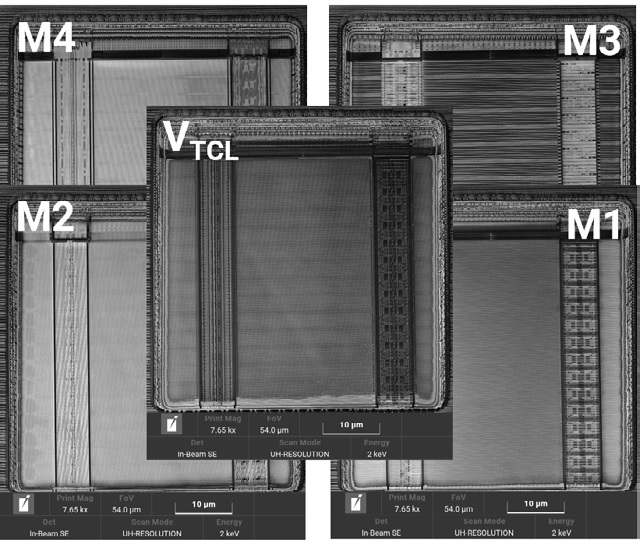

- Automated delayering through several bottom layers of 7 nm FinFET CPU (AMD Ryzen) device using Nanoflat and C-maze chemistry.

- Live peak detection on FIB end-point signal during delayering process.

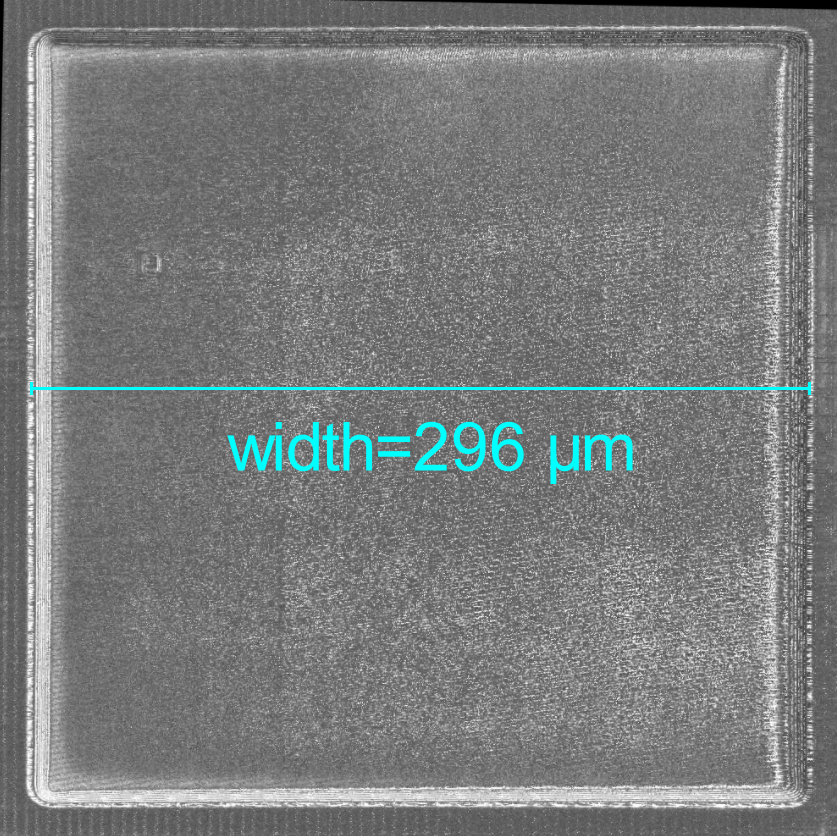

- Uniform large-area delayering (300×300 μm2) of 14 nm FinFET device.