In this work, a Ni-Ti alloy is used as a sensory material in order to quantitatively, and rather rapidly, observe compositional and/or microstructural variability in selective laser melting manufactured parts. These results provide an important first step towards understanding the nature of variability in additively manufactured parts. The TEM specimens used in this study were prepared with the TESCAN Ga FIB-SEM LYRA3 using the standard lift-out method and thinned to electron-transparency at a low ion beam energy.

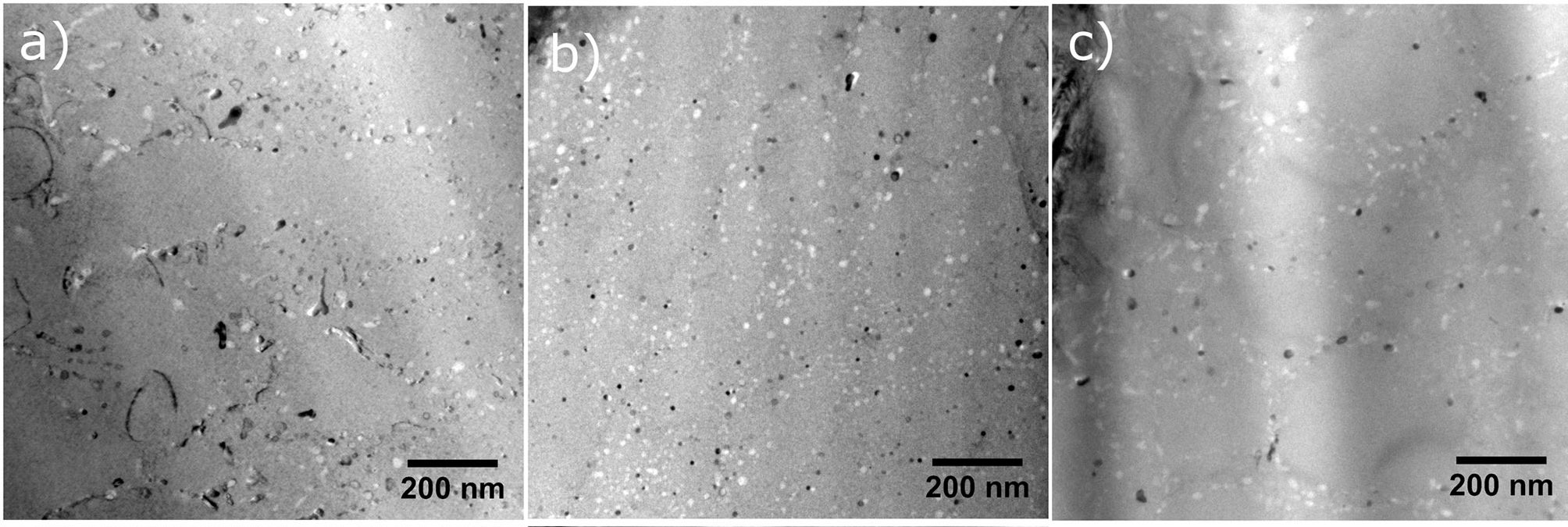

- TEM images of the AM fabricated NiTi samples showing subgrain structure and precipitates decorating the subgrains in the (a) 35 µm hatch distance sample taken from the center of the laser track, the 120 µm hatch distance sample taken from (b) the center of the laser track, and (c) the edge of the laser track.